25 Ton Electric Hoist Gantry Crane for Precasting Yard

25 ton electric hoist gantry cranes, customized for efficient heavy lifting and handling of precast concrete elements in the Philippines.

Category: Hot Sale Capacity

Your Trusted Gantry Crane Manufacturer & Supplier

25 Ton Electric Hoist Gantry Crane for Precasting Yard

25 ton electric hoist gantry cranes, customized for efficient heavy lifting and handling of precast concrete elements in the Philippines.

Customized 25-Ton Electric Hoist Gantry Cranes for Precasting Concrete Yard in the Philippines

Project Overview

This project involved the design, manufacturing, and installation of customized outdoor gantry cranes for a precasting concrete yard in the Philippines. The client required cranes capable of handling heavy concrete elements, with high lifting capacity and precision, suited for outdoor use in harsh environmental conditions.

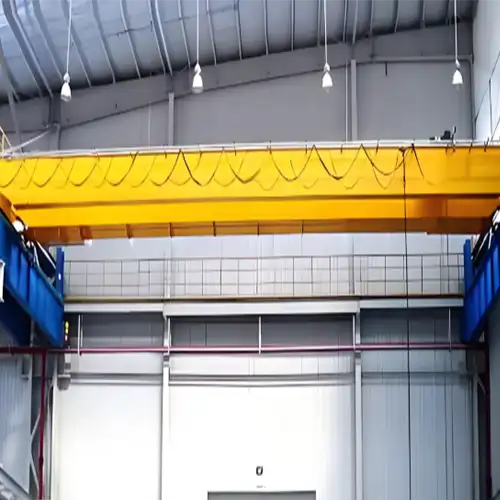

To meet these requirements, a double girder gantry crane was selected. This crane design is known for its strength and stability, making it ideal for demanding operations like precasting, where heavy loads need to be lifted and moved efficiently.

Crane Specifications

The gantry crane used in this project features an FEM advanced electric hoist trolley. This hoist system complies with the FEM standard, a European standard known for high quality and reliability. The trolley ensures smooth and precise lifting, reducing wear and tear during heavy-duty operations.

similiar project of 25 ton gantry crane double girder for precasting yard for your reference

similiar project of 25 ton gantry crane double girder for precasting yard for your reference Key specifications of the crane include:

- Capacity: 25 tons. This is enough to handle large, heavy precast concrete components, which are the primary items being lifted.

- Span: 20 meters. This span gives the crane a wide working range, allowing it to cover a large area in the yard, improving its versatility and efficiency.

- Lifting height: 23 meters. The high lifting height ensures that even taller concrete elements can be handled with ease, particularly important for lifting materials to and from elevated positions.

Project Location

This customized gantry crane was installed in the Philippines, a country with a tropical climate and diverse environmental challenges. The crane's design had to account for the region's weather, including heavy rainfall and humidity, to ensure reliable and safe operation throughout its lifespan.

Project Requirements and Objectives

Site Conditions and Challenges

The precasting concrete yard is located in the Philippines, where the tropical climate presents several operational challenges. The yard is exposed to high humidity, frequent rainfall, and occasional storms, which can affect the durability and functionality of outdoor equipment.

Challenges faced:

- Weather conditions: High humidity and heavy rain can lead to rust and corrosion, demanding corrosion-resistant materials for long-term reliability.

- Limited space: The yard space is not vast, requiring the crane to maneuver efficiently in tight areas while handling large concrete components.

- Crane mobility: The crane needed to operate smoothly on uneven ground, handling loads without causing disruptions to the workflow.

Customer's Needs

The client's main objective was to have a crane capable of efficiently handling large concrete elements with precision and speed. The key needs included:

- Heavy-duty lifting capacity: The crane needed to lift large precast concrete elements weighing up to 25 tons.

- Efficient and precise operations: The crane had to move and position the heavy loads with high accuracy, preventing damage and ensuring smooth operations.

Design and Customization Needs

To meet the specific demands of the precasting yard, the crane required several customized features:

- Enhanced lifting height: The crane's 23-meter lifting height was necessary to handle tall concrete components.

- Wide span: The 20-meter span allowed the crane to cover a large working area, increasing its efficiency in the yard.

- Crane mobility: The crane needed to be adaptable for easy movement in confined spaces, with features that enabled smooth handling of heavy loads across the yard.

Customizations were also made to ensure the crane could withstand local working conditions, including high temperatures, humidity, and occasional storms. Special corrosion-resistant coatings were applied to ensure the crane's longevity in the harsh outdoor environment.

Crane Design and Technical Specifications

Double Girder Gantry Crane Design

The crane selected for this project is a double girder gantry crane, which is known for its robust and stable structure.

Key features of the double girder structure:

- Two parallel girders: The double girder design features two large horizontal beams supported by vertical legs, creating a strong framework that can handle heavier loads.

- Increased lifting capacity: This design allows for the integration of a more powerful hoist system, making it suitable for heavy-duty applications like precasting concrete yards.

- Enhanced stability: The double girder structure provides better load distribution and stability, reducing the risk of tipping or instability during heavy lifts.

Advantages for outdoor operations:

- Weather resistance: The design is robust enough to withstand harsh outdoor conditions, including rain and humidity, ensuring the crane's reliability.

- Durability in dynamic environments: The double girder design provides the strength needed for heavy, frequent lifts, making it ideal for the constant movement of precast concrete components.

- Efficient mobility: The design allows for smooth movement along the yard, covering large spans and adjusting to the site's specific layout without compromising on safety or performance.

FEM Advanced Electric Hoist Trolley

The crane is equipped with an FEM (European Federation of Materials Handling) advanced electric hoist trolley, which is a high-standard hoisting system designed for precision and reliability.

Description of the FEM standard and its benefits:

- The FEM standard is widely recognized in the crane industry, focusing on high performance, safety, and durability. It ensures that the crane meets European safety and operational standards, making it ideal for heavy-duty applications.

- Cranes built to FEM standards are energy-efficient, reliable, and capable of working in demanding environments, such as precasting yards.

Features of the advanced electric hoist trolley used in the project:

- Precise control: The hoist trolley provides smooth, controlled lifting and lowering, allowing operators to position heavy concrete elements accurately.

- Powerful motor: The hoist system uses a powerful motor, allowing the crane to handle up to 25 tons with ease.

- Safety features: The hoist trolley is equipped with built-in safety mechanisms, such as overload protection and emergency stop features, ensuring safe operation in the high-stress environment of a precasting yard.

Crane Capacity and Dimensions

The 25 ton lifting capacity is the core feature that enables the crane to handle the large, heavy precast concrete components typical in this type of operation.

Detailed explanation of the 25 ton lifting capacity:

- The crane is designed to lift concrete elements weighing up to 25 tons, allowing it to move a wide variety of precast components, from beams to slabs, efficiently and safely.

- The heavy-duty hoist system ensures the crane can lift these loads without compromising on speed or stability, even when moving large, bulky items across the yard.

How the 20m span and 23m lifting height are optimized:

- The 20-meter span enables the crane to cover a significant working area within the yard, providing flexibility in reaching different zones of the site without needing to reposition the crane frequently.

- The 23-meter lifting height allows for vertical lifting of large concrete components, especially useful for loading and unloading materials onto elevated platforms or moving precast elements between different levels of the yard. This increased height makes it possible to handle taller concrete elements without obstruction, improving efficiency during operations.

Customization and Tailored Features

Outdoor Customization for Harsh Conditions

Given the location of the precasting concrete yard in the Philippines, the crane needed to be tailored to withstand the country's tropical climate, characterized by high humidity, heavy rainfall, and the occasional typhoon.

Protection and adaptation for outdoor use:

- Corrosion-resistant coatings: To protect the crane from rust and deterioration due to the humid and salty air, special anti-corrosion coatings were applied to the crane's structural components. This ensures the crane's longevity and minimizes maintenance costs over time.

- Weatherproof components: All electrical systems and mechanical parts exposed to the elements were equipped with weatherproof enclosures and seals to prevent water ingress, which could cause damage to vital components.

- UV protection: The crane's exterior parts were also treated with UV-resistant materials to prevent degradation caused by the strong tropical sun, maintaining both the crane's performance and appearance over time.

These customizations ensure that the crane can operate reliably under the challenging weather conditions of the Philippines while minimizing downtime caused by environmental factors.

Enhanced Mobility and Operational Efficiency

The precasting yard has a dynamic working environment, with heavy concrete elements frequently being lifted, moved, and positioned in tight spaces. The crane had to be customized for mobility, precision, and speed to meet these specific needs.

Customization of crane mobility:

- Smooth, easy movement: The crane was equipped with high-quality wheels and a motorized trolley system, allowing it to move smoothly across the yard's surface, even on uneven or slightly sloped ground.

- Compact design for confined spaces: The crane's overall design was optimized for compactness, making it able to move within narrow aisles and tight corners without sacrificing its lifting capacity or stability.

Features for high-speed operations and precision movements:

- Advanced control systems: The crane was fitted with precision control systems, allowing operators to perform quick, accurate lifts and placements of heavy precast concrete components. These systems ensure minimal movement time, enhancing overall productivity in the yard.

- Variable speed control: The crane features variable speed controls that allow operators to adjust the speed of the trolley and hoist for different tasks. Whether lifting heavy loads slowly for precision or moving lighter loads quickly, the crane can adapt to the specific operational requirements of the yard.

- Optimized for tight spaces: The crane's small footprint and high maneuverability enable it to work in confined spaces without obstruction. This is particularly important in a precasting yard where various operations must occur simultaneously in limited space.

Together, these customizations make the crane not only adaptable to the challenging outdoor conditions but also highly efficient in performing complex tasks within the dynamic, fast-paced environment of a precasting concrete yard.

main girder of double girder gantry crane for sale the Phillippines

Supporting Legs of double girder gantry crane with European style

Details of double girder gantry crane 25 ton

25 ton electric hoist trolley for your reference

Performance and Operational Benefits

Increased Productivity

The customized gantry crane significantly enhances productivity in the precasting concrete yard. By providing a reliable, high-capacity solution, the crane streamlines many aspects of the yard's operations.

How the crane helps streamline precasting operations:

- Efficient lifting and placement: The 25 ton lifting capacity allows for the swift movement of heavy concrete components. This reduces the time required for loading, unloading, and transferring materials, allowing workers to focus on other tasks while the crane handles the heavy lifting.

- Fewer crane repositioning needs: The 20-meter span enables the crane to cover a large portion of the yard without needing constant repositioning. This minimizes downtime between lifts, resulting in more continuous and productive operations.

Impact on workflow efficiency:

- The crane's ability to handle large, heavy precast components quickly and precisely improves overall workflow efficiency. Instead of relying on multiple smaller lifting devices or manual labor, the single crane can efficiently perform tasks that would otherwise take much longer, boosting output and reducing labor costs.

- The speed and precision of the crane also reduce the risk of damage to concrete elements during lifting, leading to fewer delays in production.

Durability and Longevity

The durability of the crane is crucial to its performance over time, especially in an outdoor, heavy-duty environment like a precasting yard. The customized design enhances both strength and resilience, ensuring reliable operation for years.

Benefits of design in terms of long-term operational durability:

- Corrosion-resistant materials and weatherproof coatings ensure that the crane remains operational despite exposure to the harsh elements, such as high humidity and heavy rain.

- Heavy-duty components designed for continuous, high-load operations provide a longer lifespan. The double girder structure and FEM-standard hoist trolley are designed to handle heavy loads consistently without compromising performance.

Maintenance requirements and reduced downtime:

- Low-maintenance design: The crane's advanced hoist system and robust construction reduce the frequency of maintenance required. Weatherproofing and corrosion-resistant materials further minimize wear and tear, lowering the need for repairs.

- Reduced downtime: With high-quality components, the crane is less likely to experience unexpected failures, ensuring continuous operations. The crane's durability minimizes interruptions in the workflow, increasing overall productivity and reducing costs related to downtime.

Safety and Reliability

Safety is a top priority in crane operations, especially when handling large, heavy loads in an outdoor environment. The customized gantry crane is designed with numerous safety features to protect operators, workers, and equipment.

Safety features integrated into the crane design:

- Overload protection: The crane is equipped with overload sensors that prevent the hoist from lifting beyond its capacity, ensuring the safety of both the load and the crane's structural integrity.

- Emergency stop systems: The crane is fitted with emergency stop mechanisms that allow operators to halt the crane in case of an emergency, preventing accidents or injuries.

- Anti-collision systems: The crane features anti-collision technology, which helps prevent accidents in confined spaces or areas with limited visibility, ensuring safe operation during high-speed movements.

Examples of safety performance during operation:

- During operation in the precasting yard, the crane's safety systems proved effective in preventing accidents. The overload protection ensured that no crane components were put under excessive stress while lifting heavy concrete components.

- Emergency stops were successfully used in high-pressure scenarios, such as during sudden weather changes, where operators had to quickly halt crane movement to avoid potential hazards.

- In tight spaces, the anti-collision systems ensured that the crane moved safely around other equipment and workers, preventing accidents in the busy, confined yard environment.

Overall, the customized gantry crane not only improves productivity but also ensures long-term operational reliability and enhanced safety, making it a valuable asset for the precasting concrete yard.

Challenges and Solutions

Overcoming Site-Specific Challenges

Operating in the Philippines presents several unique challenges, primarily due to the region's tropical climate and environmental conditions. High humidity, temperature extremes, and the presence of salt air from coastal winds can quickly degrade equipment if not properly protected.

Environmental conditions and crane design solutions:

- Humidity and temperature extremes: The crane is designed with corrosion-resistant coatings that protect against the high levels of moisture in the air, ensuring that key components such as the hoist, electrical systems, and structural parts remain intact despite the persistent humidity. In addition, the crane's parts are made from materials that can withstand the intense heat often experienced in tropical climates.

- Salt air: The salt air is notorious for accelerating corrosion. To counter this, marine-grade steel and specialized anti-corrosion coatings were used for key parts of the crane's structure, including the girders, hoist trolley, and motorized components. This protects the crane from the salt's corrosive effects and enhances its lifespan.

- UV damage: With exposure to constant sunlight, the crane's materials were treated with UV-resistant finishes to prevent the degradation of the crane's components. This ensures the crane's continued strength and performance, even under prolonged exposure to the harsh tropical sun.

Customization for Heavy Lifting in Limited Space

The precasting yard had to handle large concrete elements in a confined space, which posed a challenge for maneuvering heavy components. Given the need for a crane that could efficiently move and place these materials in tight spots, custom solutions were developed.

Solutions for maneuvering large concrete elements:

- Enhanced mobility: The crane was fitted with a motorized trolley and high-quality wheels to allow it to easily move along the yard's surface, even on uneven or slightly sloped ground. This customization ensured smooth and consistent movement of heavy concrete elements without causing damage to the yard's flooring.

- Compact design: The crane's overall dimensions were optimized for working in narrow aisles and tight corners, enabling it to work in confined spaces without obstructing other operations. The crane can lift heavy components while navigating these narrow spaces, making it well-suited for the limited yard area.

- Variable speed control: To improve precision when placing concrete elements in tight spaces, the crane is equipped with variable speed control. This allows operators to adjust the crane's speed for different tasks—slower movements for precise placement and faster movement when covering longer distances.

Integration with Existing Infrastructure

Seamless operation within the precasting yard was crucial for maintaining workflow efficiency. The crane had to work in harmony with the yard's existing layout and infrastructure.

Solutions for integration with existing infrastructure:

- Custom span: The crane's 20-meter span was tailored to fit the yard's specific requirements, ensuring it could cover the necessary working areas without overextending its reach. This design allowed the crane to effectively move and position precast elements without interfering with other equipment or operations.

- Adaptability to existing systems: The crane was customized to integrate with the existing power supply systems and control mechanisms in the yard. This ensured that the crane could be operated smoothly alongside other machinery and that operators could use familiar controls, minimizing the learning curve and maximizing operational efficiency.

- Minimal site modifications: In order to avoid major disruptions to the ongoing operations of the yard, the crane was designed for easy installation with minimal changes to the existing infrastructure. The crane's legs were constructed with adjustable mounting points, which allowed for a quick and efficient setup without requiring significant modifications to the yard layout.

In conclusion, by addressing both environmental challenges and the need for efficient heavy lifting in limited space, the customized gantry crane has proven to be a reliable and versatile solution. Through careful design and adaptation, the crane seamlessly integrates into the precasting yard's existing operations, optimizing productivity while ensuring durability and safety in the face of local environmental conditions.

Conclusion

The customized double girder gantry crane with FEM advanced electric hoist trolley has made a significant impact on the precasting operations at the yard. By providing a high-capacity, durable, and efficient lifting solution, the crane has enabled smoother workflow and increased productivity. Key benefits include:

- Increased efficiency: The crane's precision control and robust lifting capacity have streamlined the movement of heavy concrete elements, reducing the time spent on each lift and improving overall yard throughput.

- Adaptability to harsh conditions: Customization for outdoor use in the Philippines, including corrosion-resistant coatings and weatherproof components, ensures that the crane remains functional and reliable despite the region's extreme weather conditions.

- Enhanced mobility: The crane's compact design and variable speed controls have enabled efficient operation even in the confined spaces of the yard, allowing workers to move large concrete elements with precision and speed.

Customer Satisfaction

The customer has expressed high levels of satisfaction with the crane's performance, particularly in terms of its reliability and efficiency. The tailored features have successfully addressed their specific operational needs:

- Heavy lifting: The crane has met the requirement for lifting large concrete components with ease, allowing for safe and efficient handling of up to 25 tons.

- Increased productivity: The streamlined operations have contributed to a noticeable increase in yard output, with reduced downtime and fewer operational bottlenecks.

- Safety and durability: The customer has also highlighted the safety features, such as overload protection and anti-collision sensors, which have added an extra layer of confidence for operators working in high-risk environments.

Overall, the crane has exceeded the customer's expectations and significantly improved the performance of their precasting operations.

Future Potential and Further Projects

Given the success of this project, there is a clear potential for expanding the use of gantry cranes in other facilities or additional areas of the project:

- Expansion of crane fleet: The customer may look to add more gantry cranes for different sections of the yard or for future facilities, particularly as demand for precast concrete components continues to grow.

- Upgrades and technology advancements: As crane technology continues to evolve, opportunities exist to enhance the lifting systems with smart controls, automation, and AI-driven maintenance solutions. These upgrades could further improve crane efficiency, reduce operational costs, and enhance safety standards.

- Further site expansions: Should the project expand or additional yards be developed, the flexibility of the crane design means it could be easily adapted to meet new lifting and mobility needs, supporting continued growth and increased production capacity.

In conclusion, the customized gantry crane has not only met but surpassed the initial project goals, and its ongoing success lays a strong foundation for future growth, both in terms of additional equipment and potential technological advancements in the crane systems.

Main Projects

Related Products

Latest project

32/5 Ton Overhead Crane Sale in India: Case Study

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch